Application of Ruisu Yingke FPGA core board in HIL in automotive testing industry

- Time: 2024-05-23

Current status of China's automobile industry

In recent years, China's automobile industry has developed rapidly. China's automobile market is huge, and consumer demand for automobiles continues to increase. With the development of the national economy and the improvement of people's income levels, more and more people are able to buy cars, and cars have gradually transformed from luxury goods to daily consumer goods. At the same time, the Chinese government also provides very strong support for the automobile industry. The government has formulated a series of policies, such as reducing car purchase taxes and issuing car subsidies, to promote automobile consumption and industrial development. These policies have stimulated the growth of the Chinese automobile market to a certain extent. After decades of development in China's automobile industry, China's automobile market has become one of the largest automobile consumer markets in the world.

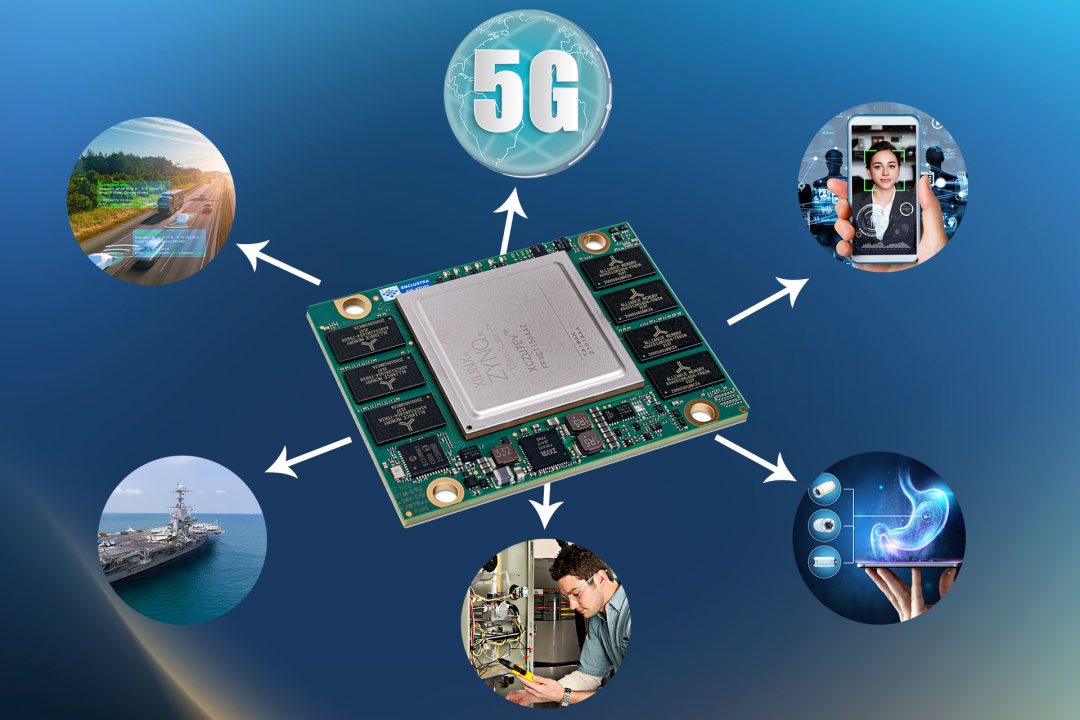

FPGA application areas

FPGAs are used in many industries and markets, including vision and AI, motion control and electrical, test and measurement, wireless communications, data centers, automotive, medical, aerospace and security, etc. With the rapid development of the automobile industry, testing is required in every link from design to manufacturing, and it is imperative to test the condition of the vehicle. FPGA is also widely used in the automotive testing industry, including testing applications in bus communication, signal detection, sensor simulation, wireless communication, human-computer interaction and other aspects. Engineers can use field-programmable gate arrays to customize the functionality of a microprocessor to meet specific, individual needs. Engineers use FPGAs to create application-specific integrated circuits. The lack of wafer capabilities makes the life cycle of field-programmable gate arrays more predictable. Other advantages include potential re-engineering, faster time to market than other solutions, and a simple design cycle.

Automotive (HIL hardware-in-the-loop) test development board

MicroNova is headquartered in Germany, and its NovaCarts brand specializes in developing HiL test systems for electronic control units (ECUs). The company has more than 35 years of experience serving automotive environments and other industries, and its ECU test solutions for electric vehicles and other e-mobility applications are among the most advanced on the market. By ensuring seamless information exchange between humans and machines, the company's 400 highly skilled technical experts are shaping the future of transportation. MicroNova uses Enclustra System of Modules (SoM) components to improve the scalability and performance of its modular NovaCarts HiL test system.

In partnership with Enclustra, MicroNova has been a leader in developing state-of-the-art hardware-in-the-loop (HiL) test systems for electronic control units (ECUs) in automotive environments and other markets. In addition to high quality, reliability and performance, the form factor compatibility of the Enclustra equipment range has proven to be key to reducing costs, workload and time.

In order to shorten users' product time to market as much as possible, Ruisu Yingke provides extensive design support and a comprehensive ecosystem for its products, providing all required hardware, software and support materials. Detailed documentation and reference designs make it easy to get started: a user manual, user schematics, 3D models, PCB footprints, differential I/O net length tables and a Linux-based board support package (BSP) are provided. Combined with ready-made backplanes and heat sinks, developing FPGA projects has never been easier.